Line Isolation and Hydrostatic Weld Testing

Bevel Tech Group is pleased to announce that it now provides line isolation and hydrostatic weld testing services.

The line isolation and hydrostatic weld testing services broadens Bevel Tech Group, Inc’s ability to better serve our customers by offering “turn key” pipe cutting, isolations, and testing services.

Our isolation/test tool can positively isolate and monitor potentially explosive vapors while performing the hot work on the upstream line. It can then be slightly moved to effectively hydrotest the new weld connection utilizing the same tool while using a minimum amount of water. This provides the customer with an approved means of isolation and weld test while minimizing the hydrotest medium amount.

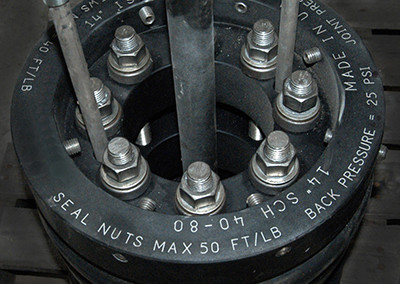

Our standard isolation/test tools range from 3/4 inches to 36 inches and are available at your request. We have the tools for multi-schedule piping and can reach test pressures up to 2250 psi. If a size larger than 36 inches is needed, contact us with your pipe size and schedule and specific info and we can see if we can supply you with one.

We have the tools and manpower to handle your everyday needs or project and turnaround needs. Call us today.

Safety Features while using Bevel Tech Group, Inc’s Line Isolation and Hydrostatic Weld Test Services

Our isolation and test tools have the ability to monitor the seals of the tool and to monitor upstream pressure while venting to a safe location. There are two o-rings that are constantly monitored by the pressurized medium filled zone in the annulus space between them. A gauge on the tool shows constant pressure, verifying the integrity of the seals and guarantees we have a positive isolation throughout the duration of the hot-work. Upstream activity is also monitored by a gauge while being vented to a safe distance from any potential ignition source.

We can circulate medium around the annulus of our tool which allows the seals to remain intact for high heat procedures such as PWHT, bake outs, or stress relieving.

Once welding has been completed, the same tool that was used for isolation can be repositioned over the new weld and a localized hydrostatic test can be performed with just ounces of water or test medium. We can test weld neck flanges, slip on flanges, socket weld flanges, orifice flanges, branch connections and more.

Benefits Of Using Bevel Tech Group, Inc’s Isolation and Test Tool

Eliminates filling lines or systems with large amounts of water or test medium

Reduces cleaning and disposal costs

Reduces the need for scaffolding

Reduces the need for blinding

Reduces testing and downtime

Chad Zeppuhar is our lead contact for Bevel Tech Group, Inc and Chad has about 20 years of experience with isolation and test tools and services. Contact Chad at 225-677-8276 (Office) or via cell phone at 225-806-1057.